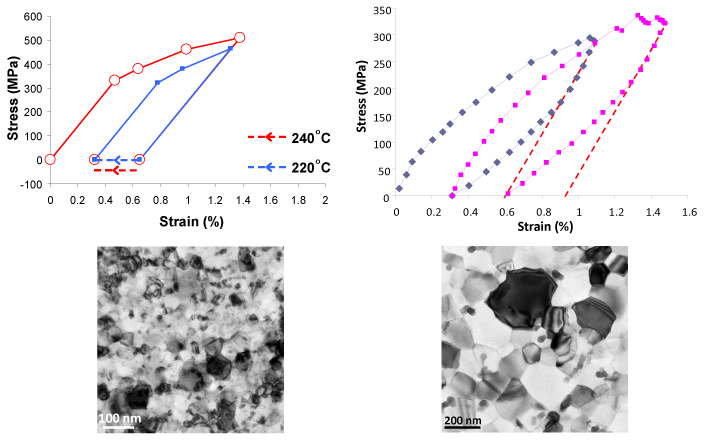

The mechanical behavior of nanocrystalline (NC) metals differs considerably from coarse-grained metals. Typically, NC metals exhibit significantly higher strength than coarse-grained metals but their ductility is often quite limited. More interestingly, NC metals also show several unusual mechanical behaviors. For example, NC metals recover significant amount of plastic deformation, which is usually considered permanent, after unloading. An example of such deformation recovery in a NC aluminum film (mean grain size of 65 nm) is shown below. At slightly larger mean grain sizes (100-200 nm), this recovery occurs even before complete unloading, resulting in a large early Bauschinger effect (see below).

We first demonstrated these effects in nanoscale aluminum and gold films, however other researchers have subsequently shown that bulk (mm sized) NC metals also exhibit these characteristics. More importantly, these phenomena appear to be common to all NC face centered cubic metals and is independent of their synthesis method or the mode of deformation. We have further shown that this unusual strain recovery is a direct consequence of microstructural heterogeneity (variation in size and orientation of grains) and that this recovery is substantially reduced when the microstructure is made more homogeneous.

Our current research is aimed at understanding several unexplored facets of this strain recovery. Among other things, we are interested in the following questions

- What is the optimal microstructure for maximizing strain recovery?

- What is the limit of strain recovery and can it be sustained over multiple deformation cycles?

- Can the recovery temperature be controlled by varying the degree of microstructural heterogeneity?

Related publications

1. J. Rajagopalan, J. H. Han, and M. T. A. Saif, “Plastic deformation recovery in freestanding nanocrystalline aluminum and gold thin films,” Science 315, 1831-1834, 2007 (pdf)

2. J. Rajagopalan, J. H. Han and M. T. A. Saif, “Bauschinger effect in unpassivated freestanding nanoscale metal films,” Scripta Materialia 59, 734-737, 2008 (pdf)

3. J. Rajagopalan and M. T. A. Saif, “Effect of microstructural heterogeneity on the mechanical behavior of nanocrystalline metal films,” Journal of Materials Research 26, 2826-2832, 2011 (pdf)

4. J. Rajagopalan, J. H. Han and M. T. A. Saif, “On plastic strain recovery in freestanding nanocrystalline metal thin films,” Scripta Materialia 59, 921-926, 2008 (pdf)

5. J. Rajagopalan, C. Rentenberger, P. H. Karnthaler, G. Dehm and M. T. A. Saif, “In situ TEM study of microplasticity and Bauschinger effect in nanocrystalline metals,” Acta Materialia 58, 4772-4782, 2010 (pdf)