In situ TEM deformation is a key technique to probe the deformation mechanisms of ultrafine-grained and nanocrystalline metals. But obtaining statistically meaningful information about microstructural changes using conventional bright-field/dark-field imaging or diffraction techniques is time consuming.

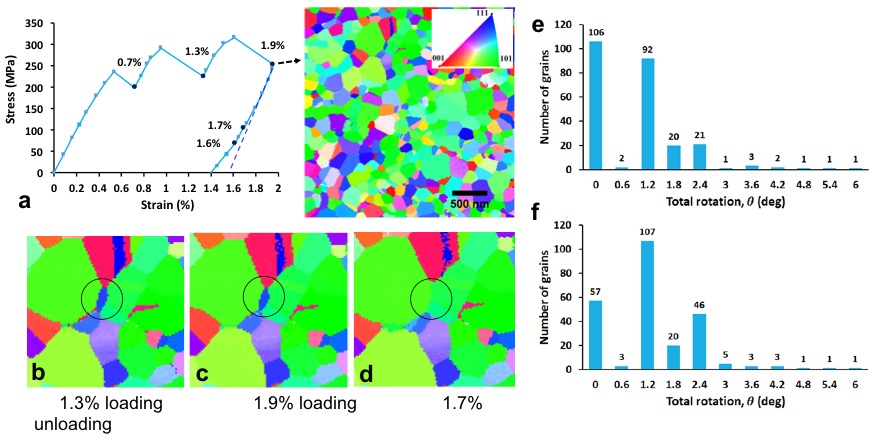

We have used in situ TEM deformation with automated crystal orientation mapping (ACOM-TEM) to track orientation changes in hundreds of grains in freestanding ultrafine-grained aluminum films, while simultaneously measuring its macroscopic stress-strain response. Our results show extensive grain orientation changes during loading, with both the fraction of grains that undergo rotations and their magnitude increasing with strain. The rotations are partially or fully reversible in a significant fraction of grains during unloading, leading to notable inelastic strain recovery. More surprisingly, a small fraction of grains continue to rotate in the same direction during unloading, even when the applied stress has been reduced significantly. The ACOM-TEM measurements have also provided evidence of reversible and irreversible grain/twin boundary migration in the films.

a) Stress-strain response during in situ TEM tensile straining of a 200 nm thick Al film. The out-of-plane orientations of grains obtained using ACOM is shown on the right. (b-d) Size reduction and complete annihilation of a grain during loading and unloading. The corresponding strain levels are indicated below the figures. (e-f) Histogram of rotations induced in approximately 250 grains during loading from 0.7% strain to 1.3% strain (e) and 1.9% strain (f).

Related Publications

1. E. Izadi, A. Darbal, R. Sarkar, J. Rajagopalan, “Grain rotations in ultrafine-grained aluminum films studied using in situ TEM straining with automated crystal orientation mapping,” Materials and Design 113, 186–194, 2017 (pdf).