We are interested in development of scalable and cost effective three dimensional nanofabrication techniques for variety of applications. Currently, we are particularly interested in development of methods which combine fabrication approaches like deposition (CVD, ALD, EBID/FIBID, etc.), etching, casting, printing, and so on with self-assembly processes. Our previous work in this area includes 3D silicon fabrication using Metal assisted Chemical Etching, 3D self-assembly of microscale liquid marbles during water condensation, and theoretical and experimental aspects of 3D carbon nanostructure fabrication using Electron Beam Induced Deposition with application to lowering electrical contact resistance of Multiwall Carbon Nanotubes.

Silicon 3D Nanofabrication using Metal assisted Chemical Etching (MaCE)

In the MaCE process etching is confined to a small region surrounding a metal catalyst template, which can travel in three dimensions as it etches into silicon and other semiconductor materials. This method is emerging as a scalable low cost alternative to traditional microfabrication techniques and has been successfully applied to produce tilted and zigzag nanowires, helical holes, and cycloidal and spiral trenches. In this project we explore different strategies for achieving fully 3D MaCE nanofabrication through mechanical control of the catalyst motion during etching.

Nanoparticle Self-assembly into Superhydrophobic Liquid Marbles

Nanoparticles adsorbed onto the surface of a drop can fully encapsulate the liquid, creating a robust and durable soft solid with superhydrophobic characteristics referred to as a liquid marble. Artificially created liquid marbles have been studied for about a decade but are already utilized in some hair and skin care products and have numerous other potential applications. These soft solids are usually formed in small quantity by depositing and rolling a drop of liquid on a layer of hydrophobic particles but can also be made in larger quantities in an industrial mixer. In this project, we demonstrated that microscale liquid marbles can also form through self-assembly during water condensation on a superhydrophobic surface covered with a loose layer of hydrophobic nanoparticles.

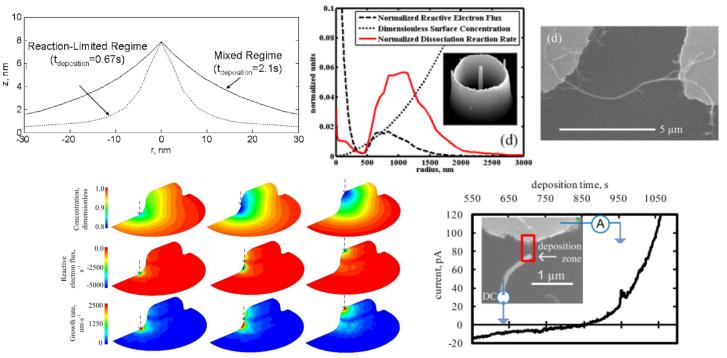

Electron Beam Induced Deposition (EBID): Fundamentals and Lowering of Electrical Contact Resistance of CNT Interconnects

In my graduate work, I studied the fundamentals of mass and electron transport in Electron Beam Induced Deposition (EBID) of nanostructures and the application of the process to lower electrical contact resistance of Multiwalled Carbon Nanotube (MWNT) and electrode junctions. I developed a comprehensive dynamic model of EBID by coupling the precursor mass transport, electron transport and scattering, and surface deposition reaction. I validated the model experimentally and used it to identify different EBID growth regimes, which affect both the growth rate and shape of the deposited nanostructures. Furthermore, I studied the formation of EBID-made carbon joint between the MWNT and the metal electrode. I determined dominant factors contributing to the overall electrical resistance of the MWNT-based electrical interconnect and relative importance of the shape and properties of EBID-made carbon contacts.