Low Carbon Cement Manufacturing

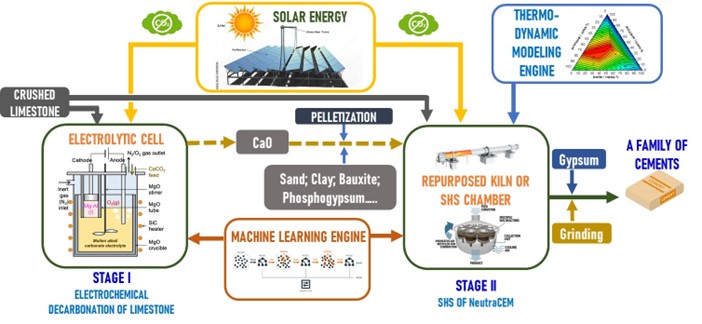

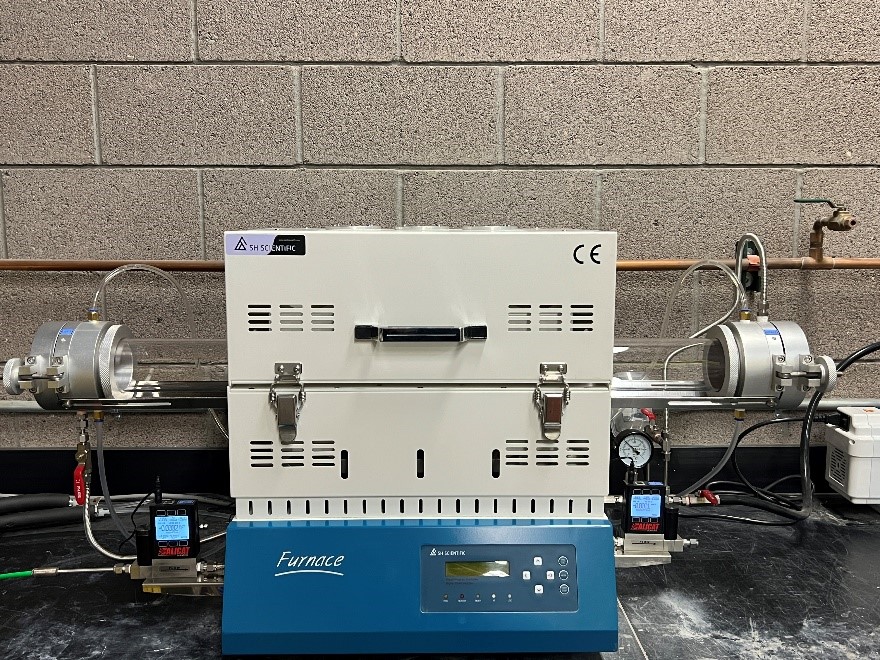

Ordinary portland cement (OPC) is the most important ingredient of concrete, which is the commodity most used by humans after water. OPC production is the second-largest single industrial CO2 emitter in the world, responsible for about 8% of global anthropogenic CO2 emissions. This accounts for about 25% of all industry CO2 emissions, and generates the most CO2 emissions per dollar of revenue. The cement industry is among the hardest to decarbonize because the direct emissions are related to the most essential chemical reactions, and processes that require high heat from fossil fuels. OPC manufacturing is also highly energy intensive, requiring ~3GJ of energy per ton, mostly supplied by fossil fuels, with about 35% of the input energy lost through different means. In terms of total energy use, cement manufacturing accounts for two-thirds of the total energy use in the production of non-metallic materials. The fundamentals of cement manufacturing have barely changed over the many decades. Limestone excavated from the earth is ground and mixed with other source materials including quartz and clay, and calcined using fossil fuels (and a mix of alternate fuels, of late; ~82% is still fossil fuel, dominated by coal and pet coke) in a long rotating kiln at high temperatures. The resulting hard clinker is cooled, crushed, mixed with gypsum (and sometimes, small amounts of limestone), and ground into OPC. The calcination process is responsible for >50% of CO2 emissions from cement production, ~40% is attributed to thermal emissions due to fuel burning, and the remaining ~10% to fuels needed to mine and transport the raw materials, and grind the clinker. CAMMS focuses on low carbon manufacturing approaches for cement that capitalizes on advances in novel materials synthesis, new pathways to provide energy for the manufacturing process, and enabling reactions at a lower temperature so that the use of fossil fuel can be minimized. Our approach is designed to uncover aspects related to fundamental materials chemistry and processing that enable manufacturing of eco-friendly cements. Processes for separating lime from limestone or from other calcium bearing materials are also considered.