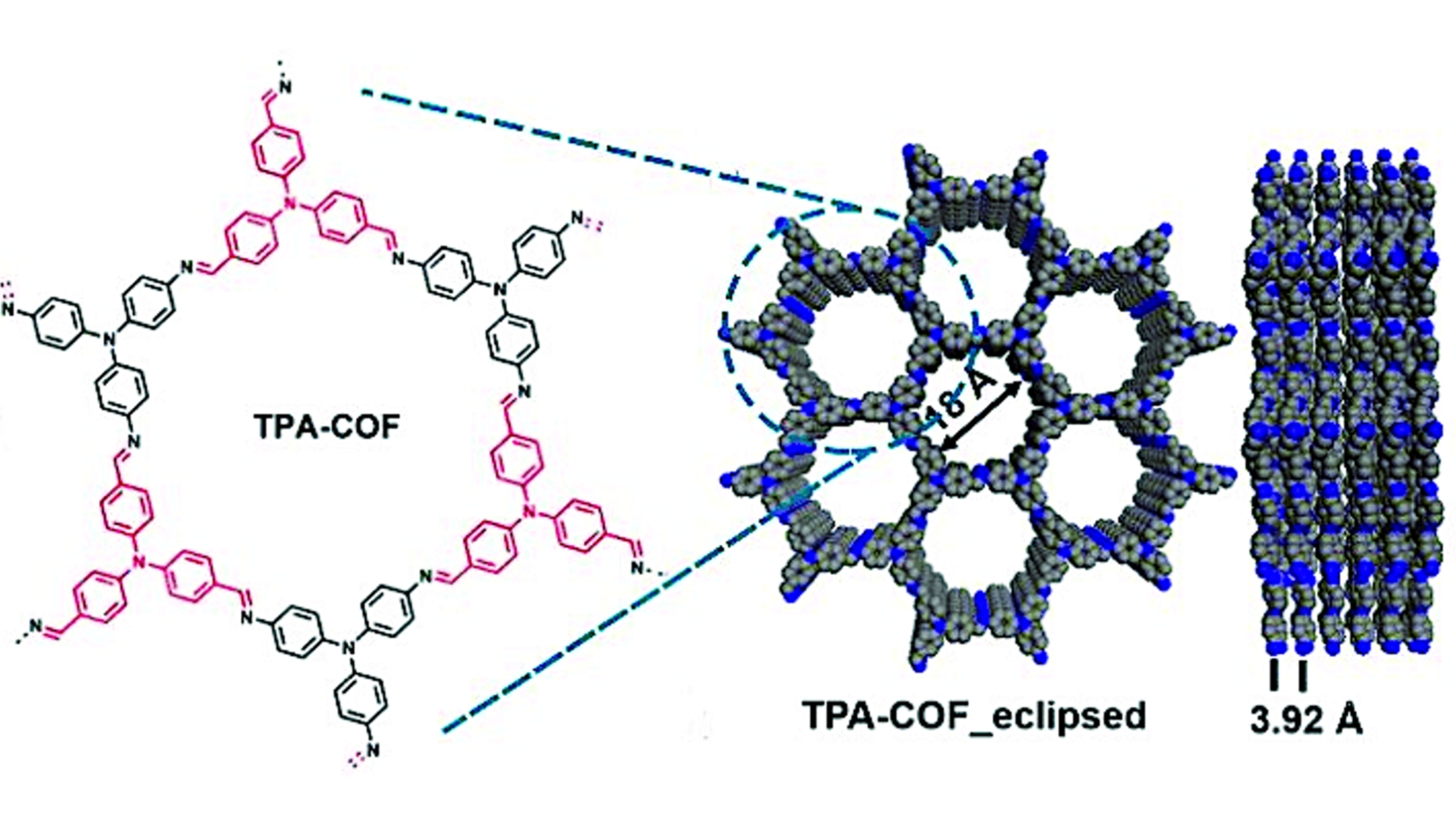

Covalent organic frameworks (COFs) are an emerging class of crystalline, porous polymers, constructed by covalently linking organic small molecules via dynamic covalent chemistry (e.g., reversible boronate ester and imine reactions) into extended networks with periodic skeletons and ordered nanopores. Unlike traditional organic polymers, COFs exhibit long-range order and permanent porosity. Due to their high surface area, tunable pore sizes, and robust stability, COFs hold promise for applications such as separation, gas storage, sensors, catalysis, energy storage, and optoelectronic devices. A central problem in this field is that COFs obtained from typical solvothermal syntheses are almost always insoluble and nonprocessable powders because of the strong interlayer stacking interactions, which prohibit them from being exfoliated and thereby processed into specific forms such as films and 3D objects for practical applications.

To address this challenge, our group is currently developing processable COFs. One potential approach is to leverage our expertise in stimuli-responsive chemistries to design adaptable COFs that can reversibly switch between a low crystallinity, dispersible state for processing and a high crystallinity, stable state for use (figure on the right). This research could significantly improve the processability of COFs, enabling the rational design of highly efficient membranes, CO2 sequestration devices, and heterogeneous catalysts. Moreover, the ability to exfoliate and process COFs can open up new lines of research, including those on freestanding, single-layered 2D COFs and COF-based multicomponent materials. We anticipate that this approach could be extended to exfoliate and process other layered 2D materials, including clay, graphene, and other 2D polymers.

Experiments involved in this research include synthesizing functional COF building blocks and adaptable COFs via dynamic covalent chemistries, tuning rheological behavior of 2D COF monolayer dispersions, processing COF dispersions via either spray coating or extrusion printing, characterizing the final properties of the resulting COFs (e.g., crystal structure, surface area, and morphology characterized using X-ray diffraction, N2 adsorption-desorption analysis, and transmission electron microscopy, respectively), and evaluating their seawater desalination and CO2 sequestration performance.