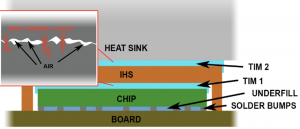

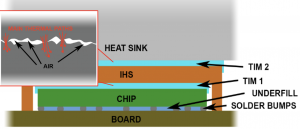

Thermal management of integrated circuits (ICs) has become a limiting factor for transistor frequency, which has stalled around a few gigahertz over the past decade. The large thermal loads stem from extremely densely packed, nanometer- sized features of modern ICs, which provide minimal surface area for dissipation of the generated heat. This limitation has motivated the development of novel thermal interface materials (TIMs) that can more efficiently conduct heat away from such hotspots.

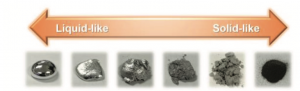

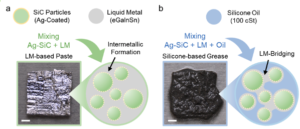

With Prof.Robert Wang from ASU and Prof. Michael Dickey from NCSU, we study fundamental parameters controlling the thermal resistances of various Liquid Metal based composite TIMs including pads composed of novel multiphase fillers dispersed in elastomer matrix, highly conductive (60 W/mK) LM pastes with tungsten particle additives, liquid metal foams, and oil-in-liquid metal emulsions.

Funding:

National Science Foundation and Semiconductor Research Corporation (past)

Kanetkar,S., Shah, NUS, Gandhi, R., Krisnadi, F., Dickey, M., Wang, R.Y.,* and Rykaczewski, K.* , Particle-assisted Oil in Liquid Metal Emulsion Formation, Journal of Physics D: Condensed Matter, (2024) (invited)

Kanetkar,S., Shah, NUS, Gandhi, R., Dickey, M., Wang, R.Y.,* and Rykaczewski, K.* , Fabrication of Multiphase Liquid Metal Composites Containing Gas and Solid Fillers: from Pastes to Foams ACS Applied Engineering Materials, (2023)

Krisnadi, F., Kim, S., Im, S., Chacko, D., Vong, M.V., Rykaczewski, K., Park, S. and Dickey, M.M.*, Printable Liquid Metal Foams That Grow When Watered, Advanced Materials, (2024).

Uppal, A., Kong, W, Rana, A., Lee, J.S., Green, M., Wang, R.Y.,Rykaczewski, K.* and Wang, R.Y.,* Pre-curing matrix Viscosity Controls Thermal Conductivity of Elastomeric Composites with Compression-activated Liquid and Solid Metallic Fillers Networks, Advanced Materials Interfaces, (2023)

Shah, NUS, Kanetkar,S., Uppal, A., Dickey, M., Wang, R.Y.,* and Rykaczewski, K.* , Mechanism of Oil-in-Liquid Metal Emulsion Formation Langmuir, (2022)

Uppal, A., Kong, W, Rana, A., Wang, R.Y.,* and Rykaczewski, K.* Enhancing Thermal Transport in Silicone Composites via Bridging Liquid Metal Fillers with Reactive Metal Co-Fillers and Matrix Viscosity Tuning, ACS Applied Materials and Interfaces , (2021).

Shah, NUS, Kong, W.,Casey, N., Kanetkar, S., Wang, R.Y.,* and Rykaczewski, K.* , Gallium Oxide-Mediated Oil in Liquid Metal Emulsions Soft Matter, (2021).

Kong, W., Wang, Z., Casey, N., Korah, M. ,Uppal, A., Green, M.D., Rykaczewski, K.* and Wang, R.Y.* High Thermal Conductivity in Multiphase Liquid Metal and Silicon Carbide Soft Composites, Advanced Materials Interfaces, (2021).

Kong, W., Wang, Z., Wang, M., Manning, K.C., Uppal, A., Green, M.D., Wang, R.Y.,* and Rykaczewski, K.* Oxide-Mediated Formation of Chemically Stable Tungsten-Liquid Metal Mixtures for Enhanced Thermal Interface Materials Advanced Materials , (2019).

Ralphs, M., Kong, W., Wang, R.Y.,* and Rykaczewski, K.* Thermal Conductivity Enhancement of Soft Polymer Composites through Magnetically Induced Percolation and Particle–Particle Contact Engineering Advanced Materials Interfaces, 1801857, (2019).

Ralphs, M., Scheitlin, C., Wang, R.Y.,* and Rykaczewski, K.* Buckling of Magnetically-Formed Filler Fiber Columns under Compression Increases Thermal Resistance of Soft Polymer Composites Journal of Heat Transfer, 141, 1, 012001, (2019).

Rykaczewski, K.* and Wang, R.Y. Probability of Conductive Bond Formation in a Percolating Network of Nanowires with Fusible Tips Applied Physics Letters, 112, 131904, (2018).

Ralphs, M., Kemme, N., Vartak, P., Joseph, E., Tipnis, S., Turnage, S., Solanki, K.N., Wang, R.Y.*, and Rykaczewski, K.* In situ Alloying of Thermally Conductive Polymer Composites by Combining Liquid and Solid Metal Micro-additives ACS Applied Materials and Interfaces, 10 (2), 2083–2092, (2018).

Doudrick, K., Liu, S., Mutunga, E., Klein, K., Damle, V., Varanasi, K.K., and Rykaczewski, K.,*Different Shades of Oxide: from Nanoscale Wetting to Contact Printing of Gallium based Liquid Metals , Langmuir, 30, 6867–6877(2014).