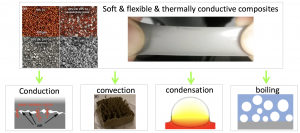

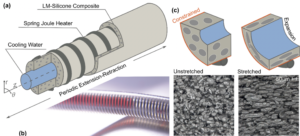

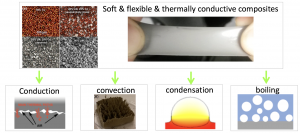

Heat transfer plays a part in nearly every industry. Consequently, finding routes of enhancing heat transfer can provide significant economic and societal benefits. Traditionally, heat transfer equipment is composed of metallic components that have hard surfaces and provide rigid structures. In contrast, my group has recently focused on quantifying improvements that can be attained by making parts of such equipment soft and flexible by employing thermally conductive elastomer composites. For phase change processes, microscopic deformation of soft surfaces occurs due to elasto-capillarity. In this area, we have already demonstrated that making hydrophobic coatings soft is detrimental for condensation heat transfer (see Phadnis and Rykaczewski, Langmuir, 2017). In contrast, we have theoretically predicted that making textured coatings soft could dramatically reduce superheat needed for onset of nucleate boiling of low surface tension liquids (see Rykaczewski and Phadnis, NMTE, 2018). Besides work on phase change processes, we are developing and experimentally validating theoretical framework for designing macroscopic shape-shifting heat exchangers that are made out of stretchable, conductive composites (see Kotagama et al., Soft Matter, 2020).