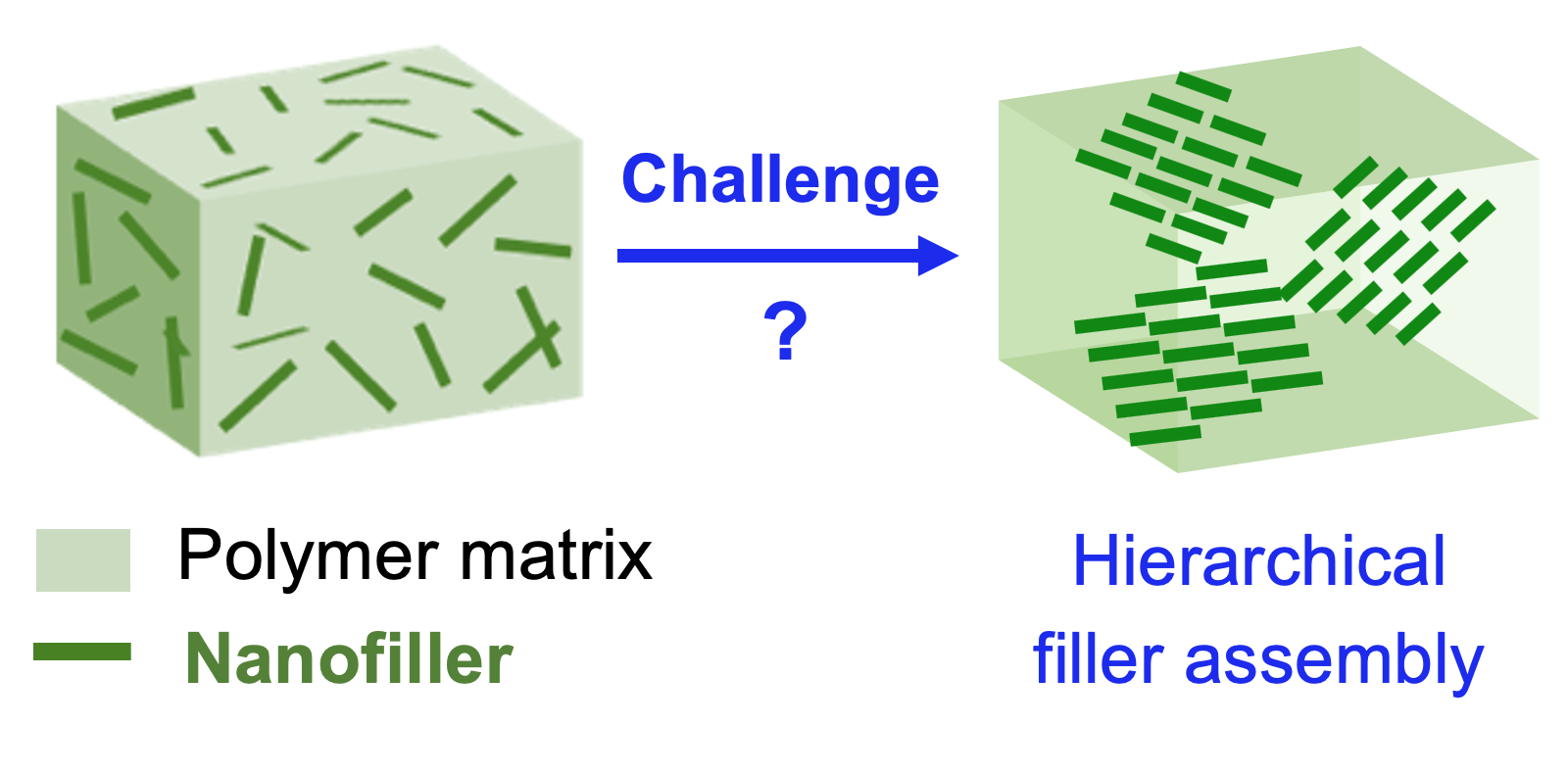

Polymer nanocomposites are comprised of polymer matrices and dispersed nanofillers (e.g., carbon nanotubes) having at least one dimension below 100 nm. A central problem in this field is that it is difficult to precisely control the spatial arrangement of the nanofillers, especially for those with asymmetric geometries – thus the promised synergistic properties (e.g., combined mechanical strength and efficient mass or charge transport) have remained hard to realize.

To address this challenge, our group is currently developing highly engineered polymer nanocomposites with precisely controlled filler arrangement and optimized macroscopic material properties. We are currently developing an 3D printing approach to fabricate polymer nanocomposites by aligning fillers in situ in a layer-by-layer fashion. Building on the layer-by-layer 3D printing process, polymer nanocomposites with directed filler assemblies in three dimensions can be fabricated. A unique advantage of this approach is that the dynamic nature of the LC template could enable the printed materials to change their structures on command to switch the macroscopic properties.

By choosing appropriate types of nanofillers, polymer nanocomposites with directed filler-mediated transport pathways for Li-ions, electrons, and water can be obtained, providing a high transport rate in the aligned state. Upon heating above a thermodynamic transition (i.e., nematic to isotropic transition) temperature, the LCs can adopt isotropic orientations and thus disassemble the filler-mediated transport pathways. Therefore, this approach could lead to stimuli-responsive polymer nanocomposites that can serve as self-protective solid-state electrolytes, electronic switches, and membranes with tunable permeability. Overall, this research can directly contribute to the fields of energy, separation, and biotechnology.

Experiments involved in this research include tuning rheology and reaction kinetics of the photocurable resins, building a UV resin 3D printer customized with a magnetic field, printing nanocomposites via LC templated 3D printing, characterizing the final properties of the printed materials (e.g., filler assembly, mechanical properties, and transport rate characterized using scanning electron microscope, tensile/impact tests, and electrochemical impedance spectroscopy, respectively), and evaluating the dynamic nature of the printed materials.