The current plastic industry is extremely wasteful and polluting: large amounts of non-renewable, petroleum-based resources are extracted to produce synthetic polymers, the majority of which have accumulated in landfills or leaked into the environment after use. This has led to a significant economic loss (~$100 billion/year) and serious environmental concerns associated with the accumulated plastic waste.

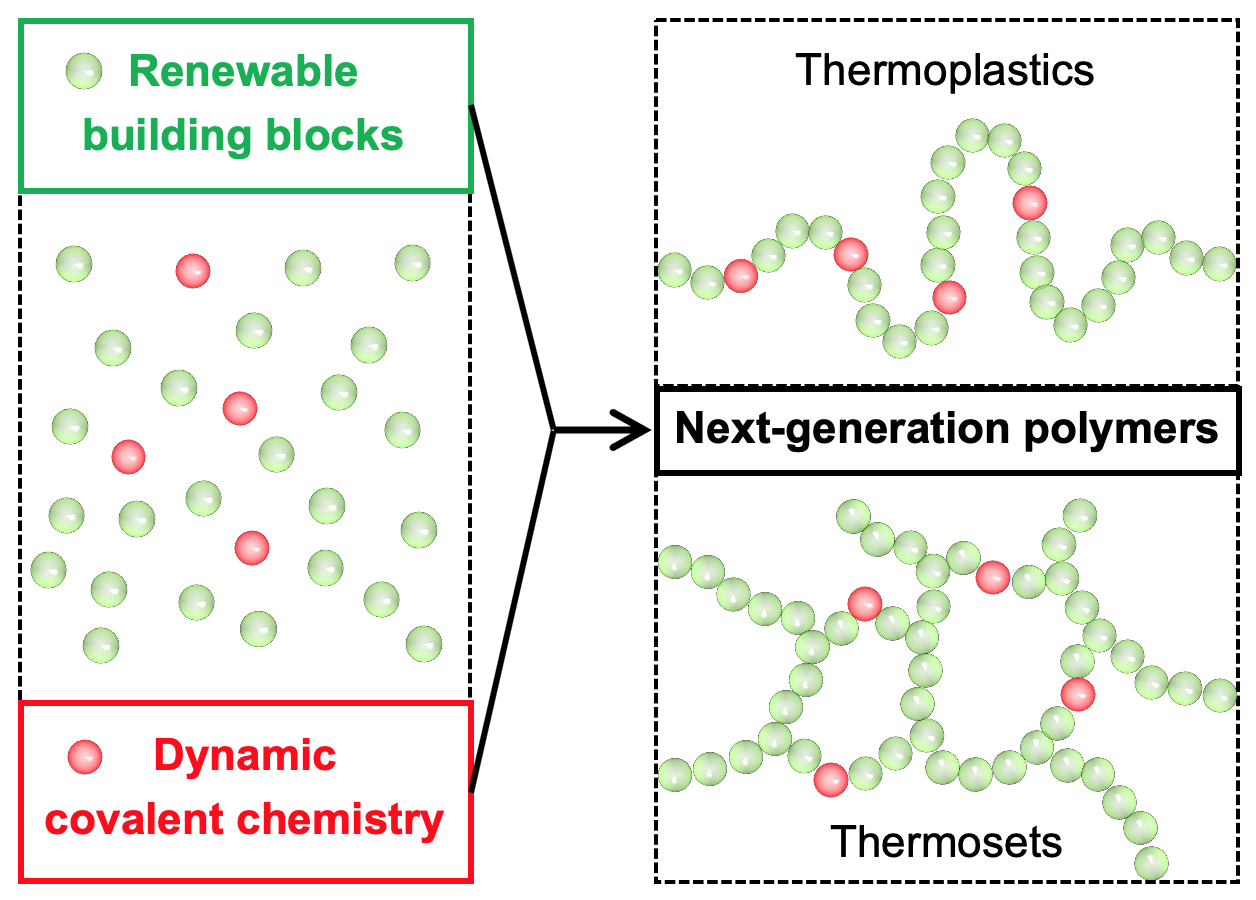

Our group is currently developing future plastics with similar or better properties and improved chemical circularity compared to current polymers. One promising approach is to integrate renewable chemical building blocks with dynamic covalent chemistries (i.e., covalent bonds that can break and reform reversibly) to design sustainable polymers at the molecular level (figure on the right). Our primary targets are newly designed polyolefins with improved mechanical recycling efficiency and polyesters with inducible and fast biodegradability. Specifically, renewable building blocks can be derived from biomass feedstocks (e.g., algae) or waste plastics. Appropriate dynamic covalent chemistries will be selected toward targeted systems.

Overall, this research could lead to strategies to transform waste plastics and renewable biomass into new plastics, which can help reduce energy needs, avoid economic loss, and alleviate environmental concerns associated with the current plastic industry. Moreover, this research could lead to a fundamental understanding of the correlation between chemical dynamics, molecular structure, and macroscopic properties, providing guidelines on how to properly process and engineer new plastics to maximize their material performance in the new circular plastics economy.

Related links:

- Youtube Plastic List on the Plastics Dilemma

- Foundations: Ellen MacArthur Foundation & Alliance to End Plastic Waste

- ASU Research Center: Biodesign Center for Sustainable Macromolecular Materials and Manufacturing (TBD)

- Other Research Centers: NSF Center for Sustainable Polymers & New Materials Institute